Optimized Flight Control

Optimized flight route, controls, altitude, aircraft weight, and total cost index.

China Airlines has committed to environmental protection and energy conservation. We sincerely care and inherit our beautiful Mother Earth.

Optimized flight route, controls, altitude, aircraft weight, and total cost index.

Improving flight plan accuracy, optimizing glide and cruise, and replacing APU with aircraft tractor power, using ground power and air conditioning systems.

Ensuring accurate refueling, optimizing selection of alternate station, reviewing fuel-saving service bulletin and technical instructions.

Intensifying engine washing operations, aircraft cleaning, aircraft resistance monitoring, onboard aviation kit checking, and GPU ground handling rate.

Reducing the weight of service trolleys and papers, optimizing the amount of water added to the aircraft, adopting new lightweight baggage container, and reducing the weight of cabin service items.

CAL periodically reviews flight routes and selects the optimal flight routes to improve flight efficiency. For example, after actively communicating and negotiating with air transport management authorities from different countries, China Airlines was granted access to a direct flight path: Taipei to Palau, thereby significantly reducing fuel consumption and enhancing environmental protection, while providing passengers with faster transportation services.

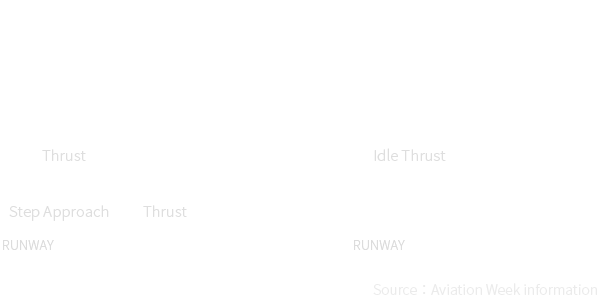

China Airlines corporate with the air traffic controllers for implementation of the CDA during non-peak period.

Save fuel consumption, reduce carbon emissions (according to the study, it can save 200 pounds fuel and reduce 630 pounds CO2e).

-23 minsFlight Time:

Flight duration reduced by 23 mins. |

-998400poundsFuel Efficiency:

Annual reduction of 998400 pound fuel usage (4 flights per week) |

-1176 10kg / NTDOperational Costs:

Cost down by $11,760 NTD (4 flights per week) |

The flight crew optimizes the flight operations at all stages, e.g., operating acceleration at optimal height, landing with low flaps, using idle reverse thrust after landing, and Engine Out Taxi to glide.

With permission by air traffic control, the flight crew is encouraged to actively request air traffic control to allow them to maintain aircraft at optimal for optimal aircraft performance.

Accurately calculate the aircraft’s optimal center gravity position and weight and balance to enhance fuel efficiency.

Calculate the flight route and altitude in line with safety and fuel saving by computer, thereby saving aircraft fuel.

In compliance with corporate environment management mechanisms of international standards ISO 14001 and ISO 50001, CAL is dedicated to the details of daily aircraft maintenance operations. Energy saving and environmental friendly applications can be spotted throughout our operation processes.

Through the implementation of energy management system, CAL oversees major energy aspects in the operating environment. In conjunction with the company's SDGs and carbon reduction targets, annual performance targets were established and executed. Key highlight measures are as follows:

For water generation, through pipeline and wastewater treatment optimization projects, business wastewater is properly treated according to regulations and permitted measures, and then applied to car washing and irrigation, etc. For water conservation, process and management improvements were made to reduce maintenance and domestic water usage. This included eco-friendly water-saving aircraft cleaning methods with 90% efficiency, and the installation of water meters for monitoring and hotspot control.

Set up professional wastewater plants and dedicated organizations for handling waste electrolyte (containing heavy metals, such as chromium and cadmium) from electroplating processes during aircraft maintenance and cleaning processes, and domestic wastewater produced within the Maintenance Park area. The Maintenance Park continues to invest in and upgrade its wastewater treatment facilities to enhance processing efficiency. Internal and external audits, along with emergency response drills, are regularly conducted to ensure high-quality treatment performance and proactive risk prevention. Sanitary wastewater (such as effluent from staff cafeterias) is first treated through oil interceptors and preliminary treatment systems to reduce BOD concentrations before being discharged to the Taoyuan Airport Wastewater Treatment Plant. This process helps maintain both the capacity and operational stability of the treatment facility.

Note: NDI: Nondestructive Inspection

Install air pollution control facilities to reduce exhaust emissions from aircraft painting or paint removal operations. CAL uses eco-friendly paints to reduce the concentration of volatile organic compounds (VOCs) produced by painting and paint removal operations. CAL also formulates plans to replace old vehicles, implements the stop idle policy, and promotes the vehicle electrification in order to reduce the environmental impact.

A goal of 100% recycling rate has been established with the annual KPIs covering waste aviation fuel, lubrication oil, waste wooden pallets, waste metal, waste solution, waste solvents, waste plastic, waste paper, waste electric wires and cables, waste light sources, and kitchen waste, etc. in order to reduce the environmental load of waste materials.

CAL's carbon reduction concept is implemented across daily office operations. We start from the details, with calculated resource consumption, of materials such as water, electricity, and paper, and thoroughly carry out our measures through implementing target management and staff education, thereby generating substantial carbon reduction benefits. The key measures are as follows:

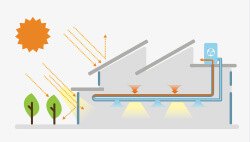

Introduced renewable energy facilities (e.g., solar photovoltaic system), adjusted lighting control zone, replaced energy saving lighting equipment, installed variable frequency drive (VFD) equipment, replaced energy-intensive equipment, optimized air conditioner settings, regularly examined electricity consumption, and promoted energy saving habits.

Gradually promoted the procurement of low-carbon / electric transportation equipment, prioritized the procurement of hybrid business vehicles, controlled the use of business vehicles, performed regular maintenance services for old vehicles, and promoted policies for low carbon drivers and combined crew vehicle schedules. Regularly review fuel consumption and promote fuel-saving/environmental driving concepts.

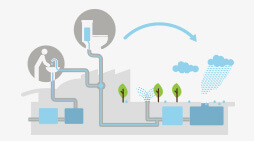

Set up rain water recycling systems, increased waste water recycling rates, adopted products with Water Conservation Mark, regularly reviewed water resource consumption, and promoted concepts of water conservation.

Promoted paperless processes, adopted double-sided printing and implemented the central system for paper package distribution.Necessary paper uses products certified by the forest sustainability related mark.

Monitored and reviewed the overall waste output, performed waste management using five major principles: Refuse, Reduce, Reuse, Recycle and Repair, to increase rate of recycle and reduce use of waste products.

CAL designed and developed its global headquarters with four major indicators of green building: "Green area," "Base Water Conservation," "Daily Energy Saving," and "Water Resources". Prior to commencing operations in 2010, CAL obtained a Green Building Candidate Certificate. By ongoing improvement in management and hardware enhancements, the Headquarters Administrative Center and Crew Center obtained the Diamond-level Green Building Certification from the Taiwan Ministry of the Interior since 2017. Moreover, CAL actively introduce renewable energy, such as installing “Electric Power Regeneration Device” and “Solar Photovoltaic Device.” The overall spontaneous power generation is mainly for self-use, and has obtained the National Renewable Energy Certificate (T-REC), actively responding to Taiwan renewable energy development policy.

Low-E (low radiant) glass and sun shading boards are used in exterior walls to reduce radiant heat. In cooler seasons, natural ventilation and roof heat insulation devices are used to reduce the use of air conditioning and thereby saves energy. Fine lighting can also reduce lighting loads.

Use the systems of VFD Chiller which can automatically control the number of units according to the temperature and loads. The systems can save 20% electricity consumption than non-variable frequency systems. We also set up the office circulation fans to adjust indoor wind field and have better comfort environment for staff.

Open windows to let in the natural sunlight and use the high-efficiency lamps in office area, such as energy-saving label LED lamps with one-by-one configuration and hand loops.

Depending on the power consumption of CAL headquarter, the contractual capacity of the electricity gradually reduced from 6,000KW in 2010 to the current 2,700KW.

CAL is actively evaluating and introducing renewable energy, such as the installation and grid connection of “elevator power regeneration devices” and “solar photovoltaic facilities.” The overall self-generated renewable electricity is mainly for self-use. CAL has obtained the national “Taiwan Renewable Energy Certificate” (T-REC), actively responding to Taiwan’s renewable energy development policy.

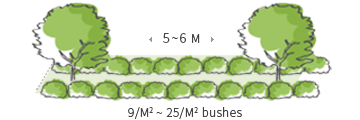

A multi-layer planting method is adopted; Trees on the upper layer have a space of 5 to 6 meters in between, so that seedlings can have sufficient room to growth, whereas every 9 to 25 bushes on the lower layer occupy a space of one square meter. The green space follows the principle of using native tree species and seasonally colorful plants.

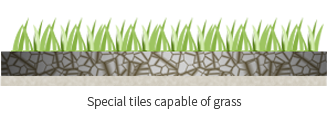

Water retention is part of the ecological water cycle. China Airlines expanded the green spaces and covered them with special titles capable of grass to boost the site's permeability and water retention.

Use water-saving label products and devices, including water-saving faucets and toilets, automatic flushing sensor system and off-peak electricity timing irrigation system. All of these devices can save 15% to 20% of water use.

Set up a rainwater recycling system and adjust the pipeline to recycle from the reclaimed water of central water dispenser and the crew training pool, and to use it as toilet water and watering garden plants. The recycling water system has a capacity of 1,300 tons.

Adopted the central drinking water system, the drinking water end has both energy-saving and water-saving labels, and the water is regularly tested in accordance with drinking water quality standards.

Based on different spatial characteristics of the three buildings, central air-conditioning and outside air ventilation systems are installed, and the indoor plants are also placed inside the office to provide better air quality, and the quality is regularly checked with instruments.

The offices, general training classrooms, and meeting rooms are furnished with eco-friendly materials that promote health, including water-based eco-friendly paints and lightweight partition walls. These materials have low emissions, low pollution, and low odor that could minimize health hazards.

Major building materials, including structural steels, roofs, wall metal panels, glass curtains, natural stones etc., are all recyclable. Recycle and reuse waste resources at the construction sites. For example, concrete chunks are shattered and further used as the material for roadbeds in the CAL Park area.

"T"shaped flight simulator building pays attention to privacy. Generator and simulator devices requiring no lighting are placed in the central space, whereas offices having lighting requirements are horizontally distributed on the two sides to take advantage of natural lighting.

"H"shaped training and dispatching building is equipped with large-sized training facilities on both sides and designed with high ceiling. Dorners and curtains are also used on both side to let in sufficient natural lighting.

"–"shaped headquarters building has a long and balanced space planning for offices and used curtains on both sides to let in sufficient natural lighting.

To minimize waste sent to landfill and move toward a zero waste to landfill goal, China Airlines follows a tiered waste management strategy based on the principles of Refuse, Reduce, Reuse, and Recycle. The company has implemented various waste reduction measures, including proper waste sorting, toxicity reduction initiatives, and active collaboration with recycling vendors to establish closed-loop recycling processes. These efforts ensure that packaging and other operational waste generated across the Group is effectively recycled and diverted from incineration or landfill. Even for waste that must be incinerated, China Airlines aims to utilize waste-to-energy (WTE) solutions to recover thermal energy for electricity generation, landfill diversion rate reaches 97.5% in 2024. In response to global concerns over packaging, single-use plastics, and food waste, China Airlines—though not a direct manufacturer—actively engages with suppliers to align on environmental trends, integrate circular economy principles, and co-develop eco-friendly and plastic-reducing in-flight service items.

| Objectives | 2025 | 2030 | 2040 |

|---|---|---|---|

Recycle general recyclable waste |

100% | ||

Reduce general unrecyclable waste output

|

7% | 12% | 15% |

Increasing industrial waste recycling ratio |

45% | 50% | 58% |

Reducing paper consumption

|

30% | 50% | 52% |

| Objectives | 2025 | 2030 | 2040 |

|---|---|---|---|

Reduce total cabin waste

|

50% | 65% | 70% |

Reduce use of single use plastic items and packaging for in-flight services |

90% | 100% | 100% |

Use of sustainably certified paper and wood-based catering supplies |

10% | 50% | 80% |

Note 1:The scope of the in-flight waste reduction target includes non-recyclable waste and paper from flights returning to Taiwan.

Passenger support drives China Airlines’ progress toward environmental sustainability. We offer diverse eco-friendly services and engage passengers in sustainability efforts. Through multiple channels, we communicate environmental insights, corporate actions, and performance to cultivate a green culture internally and strengthen our environmental brand externally.

In addition, to strengthen external communication and establish a deeply rooted sustainable brand image, China Airlines actively discloses its environmental philosophy and performance results (including an annual environmental performance At a Glance) through platforms such as social media and the in-flight magazine on a regular basis. These efforts aim to build and promote awareness of green consumption.

Improve employees' recognition and awareness for environmental protection and sustainability, and then develop good daily behavior and habits.

CAL published 20 articles and reports on environmental sustainability through internal communication platforms, such as employees' email, China Airlines newsletter, and the startup screen, in 2024.

To enhance and deepen environmental awareness among all employees, China Airlines conducts an annual rewarded survey to assess staff satisfaction with environmental information promotion and gather improvement suggestions. In 2024, a total of 3,749 employees participated, achieving an overall satisfaction rate of 95.2%

China Airlines holds annual environmental seminars. In 2024, the theme was "The Four Seasons of Taiwan’s Forests: Lessons from the Mountains," featuring Ms. Yang from the Forest Recreation Division of the Hsinchu Branch, Forestry and Nature Conservation Agency, Ministry of Agriculture, who shared insights on managing Taiwan’s forest recreation areas.

Speaker: Ms. Shu-Han Yang, Forest Recreation Division, Hsinchu Branch, Forestry and Nature Conservation Agency, Ministry of Agriculture

Photo of the speaker with in-person and online participating colleagues

CAL organizes training on environmental and energy management every year for the related competent personnel of the Company and affiliates, and selects dedicated staff to participate in external training and seminars as needed.For past performance, please refer to the Corporate Sustainability Report.